The Evolution of The Surf Leash

The story of the surf leash can be captured in the life of one person - John Malloy. While John wasn’t the only one using and making leashes in the 70s, his commitment to solving their pain points one problem at a time is legendary. By giving things a go, testing, refining and evolving, John was able to bring surf leashes from a sock tied to a piece of rope into the tech piece of equipment they are today. His innovations and insights have also brought return rates from breakages from basically 100% from when he started down to almost zero.

The journey began when John landed in West Oz in 1974, after hitching a ride on a freightliner through the Pacific with just a backpack and a surfboard...

A Rugged Testing Ground

John learned quickly after landing in West Oz that the waves served up by the Indian Ocean were nothing like back home. Raw, powerful and unforgiving, they made short work of surf equipment if you hadn’t made things tough.

“In the beginning we just thought it was gunna work. We didn’t do any testing...all of them broke...they were legropes made for California. They weren’t going to work around here.”

That failure sent John on a mission to find better materials. At first he used bell cord that was pretty strong and had a bit of give. Then, he stumbled across something that is still used in every leash around the world today…

The Ultimate Cord Material

When meeting with the rep who sold him the bell cord, John looked in the guy’s bag and went, “what’s that stuff?”. It was bright orange urethane, used by washing machine repairmen to replace fan belts. John tied some to a post at the farm he was living at, hooked the other end to a tractor and started driving. The strength was unbelievable.

“That was an instant lightbulb moment where you went, geez, this could really work,” says John.

It worked so well that the breakage point on leashes wasn’t in the cord itself anymore. The weakness was now in other parts…

A Strong Idea

Another key weak point on leashes in the past was the swivel used to eliminate tangling and twisting of the cord. Initially, surf brands used basic brass options found in fishing equipment. They jammed up, corroded and broke after repeated use.

John literally went to the drawing board and designed a dual bearing, stainless steel swivel that wouldn’t seize in saltwater. He never patented the idea and it fast-became the standard in leash components right around the globe. It’s still used in most leashes today.

The Last Big Break

Now that the cord and swivel were solved, there was one last major issue with surf leashes: they broke where the cord met the mould, which joins the leash to your ankle. Basically every leash returned back then failed at that same point. Again, John put his design hat on and came up with the DNA Flex Mould—a patented solution that keeps things stretchy without breaking. Overnight, Creature’s Leash return rates dropped to nearly zero. The last big break in leash reliability.

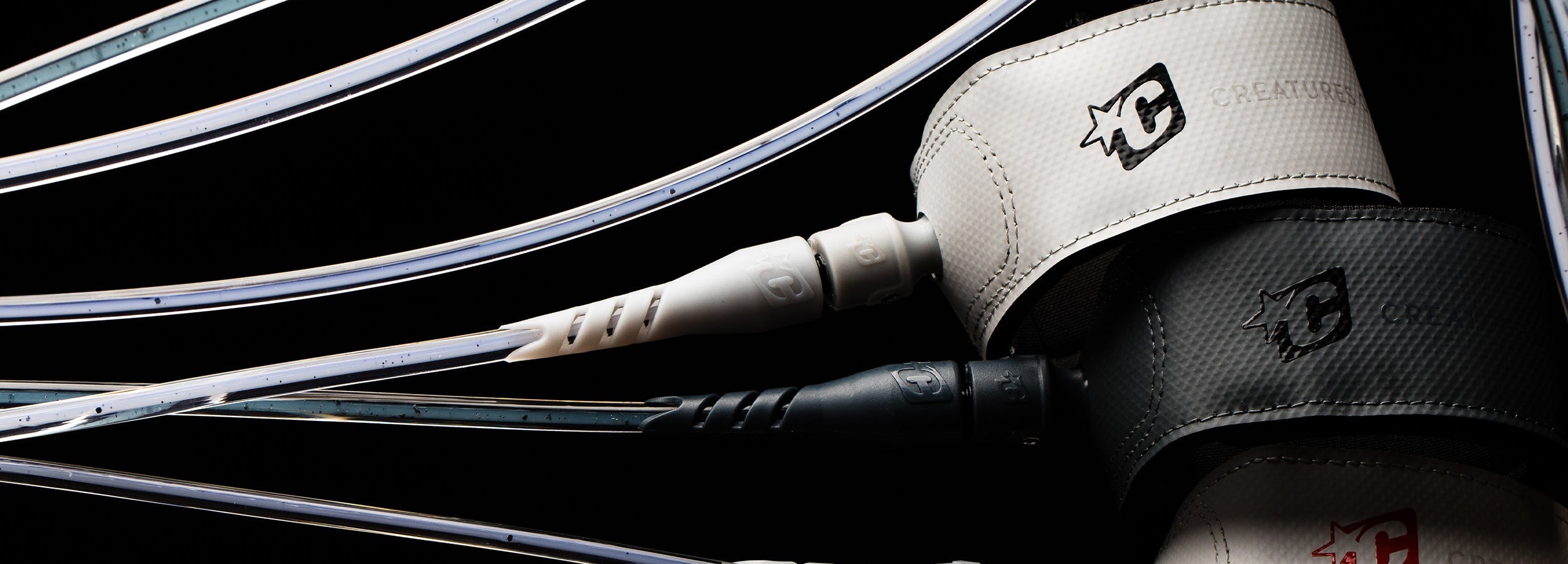

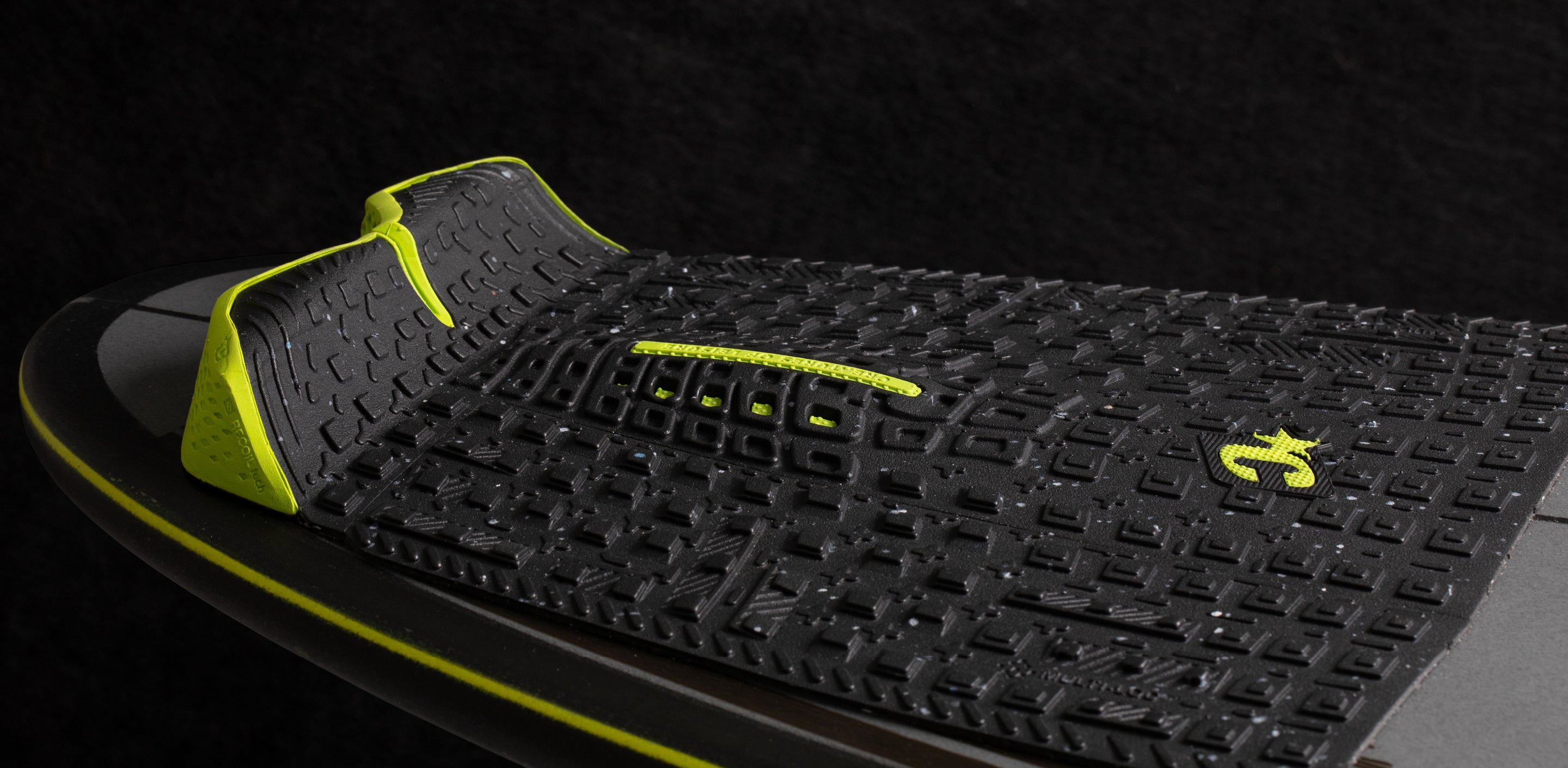

Comfort and Convenience

With the world’s most reliable leashes on lock, John and Creatures continued innovating to reduce drag, increase comfort and improve safety.

The current Creatures Superlight range combines decades of insight and innovation to include non-slip cuffs, Surefire Release tabs on the velcro, and more. The Height of Performance.

John Malloy has since retired from the surfing industry, onto his next wave of life. However, at Creatures we salute his contribution and still embody his spirit of having a go and building product for a lifetime of adventure.

As a nod to John and his legacy, the film A Creature of Leisure follows John’s journey, from a teenager looking to explore the world, to a man who’s had an immeasurable impact on our collective lifestyles.